GNEE has 16 years of experience in exporting stainless steel plates. This time, we will share a variety of processing techniques for stainless steel plates. The surface treatment techniques for stainless steel plates mainly include embossing, brushing, mirror treatment, frosting, sandblasting, etc.

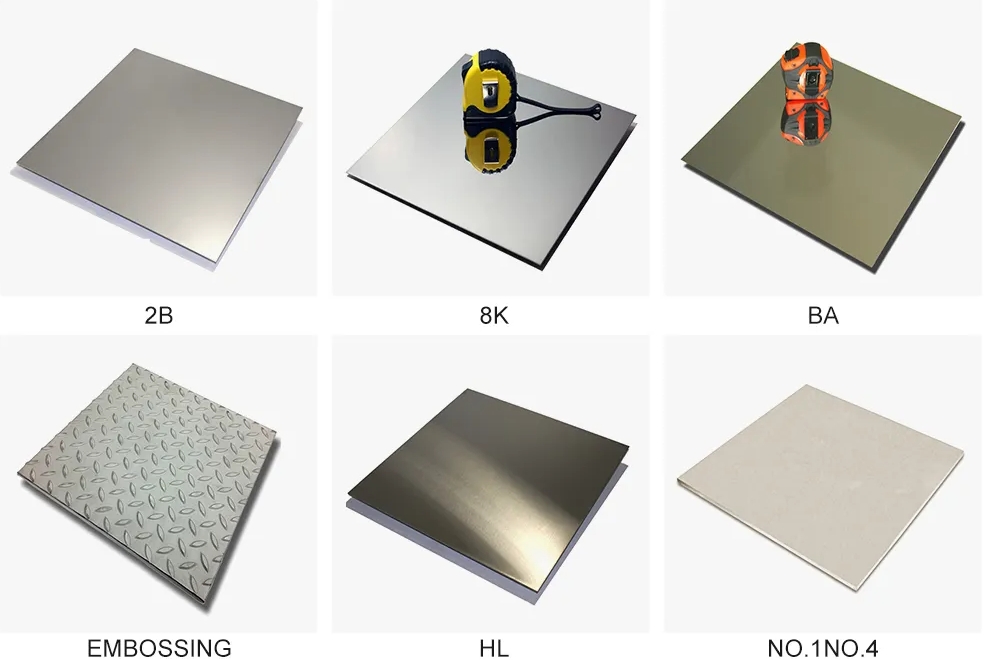

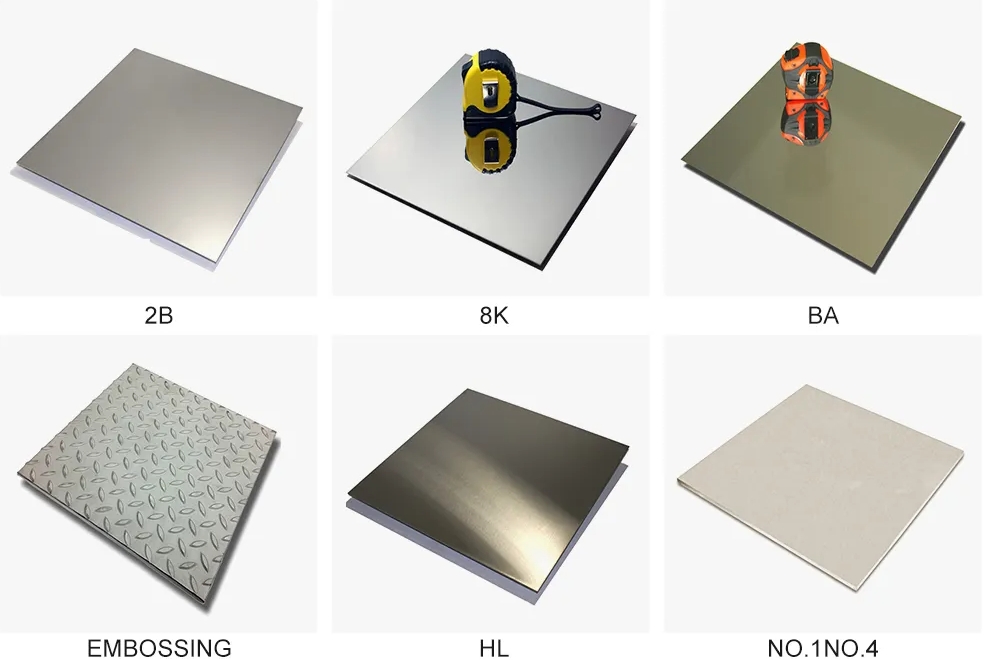

1. Commonly used decorative panels include: 2B surface, BA surface. The main difference between 2B surface and BA surface is annealing: 2B is annealed and pickled, the surface has a certain degree of oxidation, and the surface is darker, while BA is bright annealing, non-oxidized, and the surface is brighter.

2. Mirror surface: The mirror treatment of stainless steel is the process of polishing the surface of stainless steel to obtain a bright surface like a mirror. Titanium plating, etching and other process treatments can be carried out later.

The professional name of the mirror surface: 8K, its grades can be divided into: 6K, 8K, fine grinding 8K, super fine grinding 8K. The difference lies in the brightness of the surface and the control of the magic flower.

According to the different thickness of the specifications: divided into manual grinding and machine grinding: the specifications of machine grinding 8K: thickness: 0.3-3.0mm, length: more than 1.6 meters-4.5 meters. According to the thickness and processing requirements, the price of the processing is different.

Quality inspection of finished product standards: the board surface cannot have insufficient brightness, grinding head flowers, creases, damage, residual stains on the board surface, uneven film and other problems.

3. Wire drawing: also called frosting, working principle: use a high-speed rotating sand belt to grind the surface of the stainless steel plate to form regular stripes on the surface of the stainless steel plate.

Note: The larger the value of the sand belt, the finer the sand is ground. On the contrary, the finer the sand belt, the coarser the yarn grain. We usually use 320 wire drawing. Here I would like to talk about snowflake sand in particular. Snowflake sand is different from other yarn grains. The surface of snowflake sand is intermittent sand grain, also called forging grain. It is ground with a 400-number sand belt, so it is also called NO4.

Specifications of wire drawing: The base plate for wire drawing is 2B, BA, mirror plate, thickness: 0.4-3.0mm, width: 1000MM, 1219MM, 1500MM, conventional: according to needs. Different thickness and sand pattern have different processing prices.

4. Sandblasting: Working principle: Using compressed air as the power to form a high-speed jet beam to spray the material at high speed onto the surface of the workpiece to be processed, so that the surface of the workpiece can get the effect of sand grains. There should be no fingerprints, oil stains and sweat stains on the board surface during sandblasting, otherwise it will remain on the surface and cannot be removed after the processing.

Sandblasting working procedures: changing sand grains-board feeding machine-cleaning board surface-sandblasting-blowing off the floating sand on the surface-film sticking. Finished product standards for quality inspection: the board surface cannot have uneven sandblasting, yin and yang sides, fingerprints, oil stains, etc.