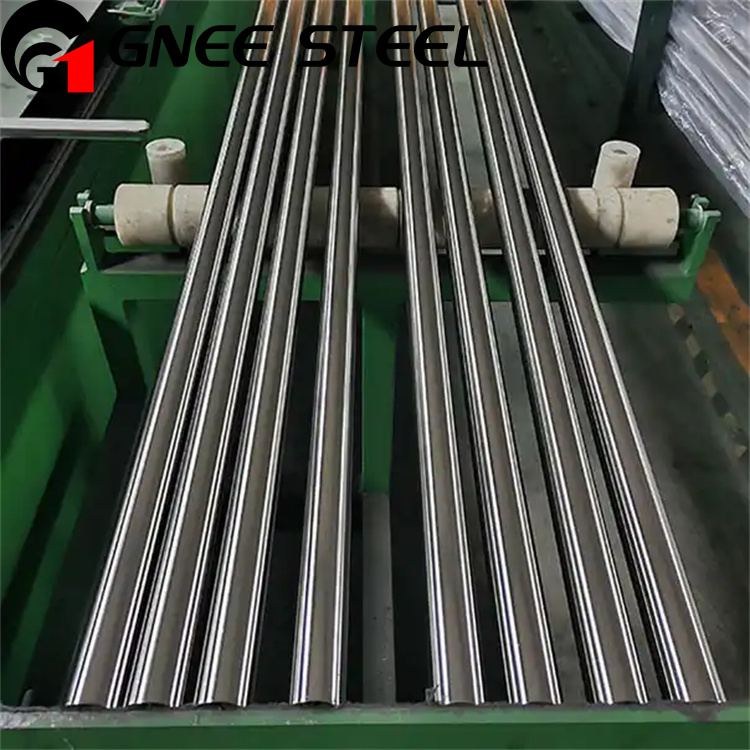

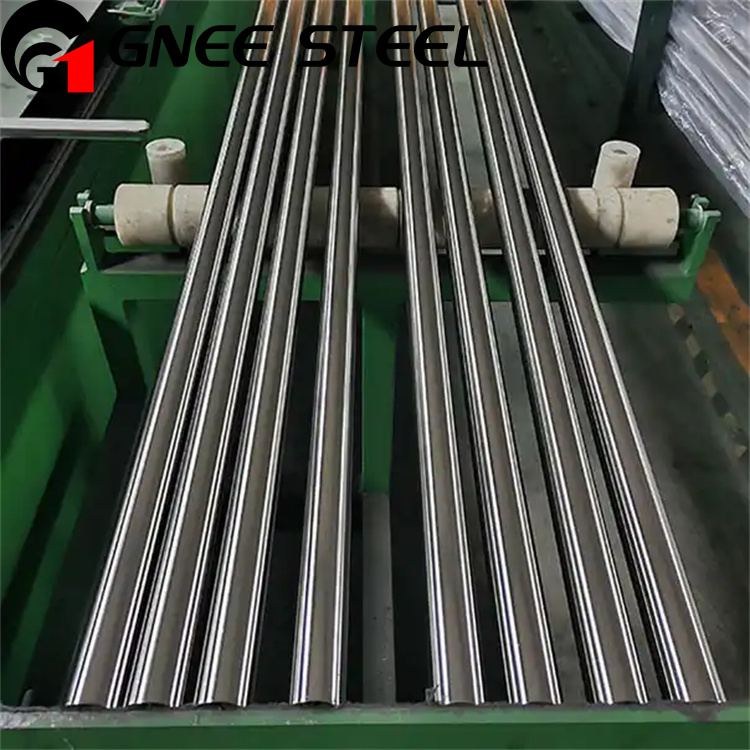

254SMO

General instructions

254SMO (UNS N31254) is often referred to as the "6% Moly" grade due to its molybdenum content. 254SMO is an austenitic stainless steel with high content of chromium, molybdenum and nitrogen, which has good resistance to pitting and crevice corrosion, especially in environments containing halide ions, such as chloride, bromide and fluoride solutions . Compared with Alloy 904L, Alloy 20, Alloy 825, 254SMO has excellent chlorination resistance and is particularly suitable for brackish water environments, such as brackish water or seawater.

What is UNS S31254? This grade of steel is super austenitic stainless steel. They are high-end stainless steels designed for impact toughness, resistance to chloride crevice corrosion, stress corrosion cracking and pitting corrosion. These are austenites with high contents of nickel and chromium.

What is ASTM A240/A240M? It is an American material standard for standard specifications of chromium and chromium-nickel stainless steel plate, sheet, and strip for use in pressure vessels and general applications.

Why is S31254 called Alloy 254 stainless steel? If the material grade is designated as stainless steel, it means that it contains chromium content, but the chromium content of this grade is higher. S31254 is a UNS designation alloy, also known as SAE designated 254 alloy, and is defined in the ASTM A240 standard.

This material grade is typically supplied in the annealed condition and provides a yield strength in excess of 300MPa. This material cannot be strain hardened by heat treatment, but harder surface toughness can be obtained by cold working. The normal pitting resistance equivalent number of this alloy is forty-two to forty-four, which ensures resistance to pitting corrosion and crevices, strengthening this alloy as a replacement for 300 series austenitic alloys (such as SUS304 type) that need more Places of high mechanical performance.

Indicative chemical composition of S31254 steel: The chemical composition of this grade is as follows:

§Carbon (C) ≤ 0.02%.

§Manganese (Mn) ≤1.0%.

§Phosphorus (P)≤0.3%.

§Sulfur(S)≤0.01%.

§The minimum percentage of chromium is 20.0%

§The minimum percentage of nickel is 18.0%.

§Silicon (Si)≤0.7%.

product specifications

254SMO Bar: ASTM A276/A479

254SMO forging: ASTM A473

254SMO board/board: ASTM A240

254SMO pipe/tube: ASTM A312

254SMO physical properties

Density: 8.0 g/cm3

254SMO mechanical properties - solid solution annealing

Tensile strength: ≥650 MPa

Yield strength: ≥300MPa

Elongation: ≥35%

Equivalent material grades in other international standards: Some equivalent standards are as follows:

§In the SAE designation, the corresponding material is called alloy 254.

§In DIN standards, the corresponding material is called 1.4547 section steel.

§In ASTM standards, the corresponding material is called F44 steel.

§In the digital standard, the corresponding material is called S31252 steel.

Applications of S31254 stainless steel: The applications are as follows:

Elevated oil distillation tower

Exhaust gas desulfurization scrubber

water pump

choke

Industrial components for oil and gas

Industrial components for food processing equipment

valve

pipeline

brine treatment

Flanges and manifolds

Industrial components for the chemical industry

Bleaching equipment in the pulp and paper industry

Desalination

Heat Exchanger