What is stainless steel? Characteristics and applications of stainless steel

Currently, stainless steel is used in many industries. In addition to traditional industries and marine construction, the use of household appliances is also increasing.

Although stainless steel is more expensive than mild steel, its superior properties extend service life and reduce recycling costs. Therefore, the larger upfront cost will pay off in the long run.

We know that steel is an alloy of iron and carbon, with a maximum carbon content of 2.1%. Stainless steel is a group of steels that are made corrosion-resistant through the addition of alloying elements.

Its distinguishing feature is its high content of chromium. Stainless steel contains at least 10.5% chromium, which increases its corrosion resistance and strength.

When exposed to air, the chromium in the alloy forms a passivating layer as it oxidizes. This layer acts as a barrier against further corrosion, essentially making the alloy rust-proof. This mechanism allows for a spotless appearance to be maintained for extended periods of time under normal working conditions.

Benefits of stainless steel

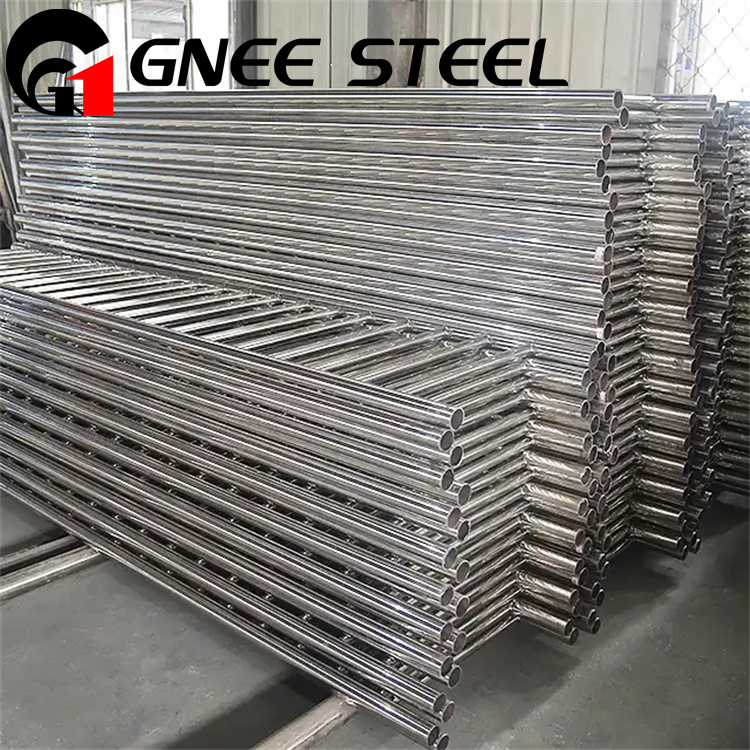

As demand increases, production increases, making it more affordable than ever. Increased demand has resulted in the availability of standard and non-standard sizes. Additionally, there are a variety of stainless steel finishes available.

In addition to polished finishes, a range of patterned and colored surfaces are also available. This makes it possible to find an option that suits your needs.

Stainless steel is also 100% recyclable. In fact, half of stainless steel production comes from scrap metal. This makes it a relatively environmentally friendly material.

Example

Stainless steel is an extremely versatile material. It is preferred where both the properties of steel and corrosion resistance are required.

Its first use was in tableware because of its superior corrosion resistance. Next, the road opened to the chemical industry. Today, we see stainless steel almost everywhere.

Use cases vary by industry. For example, uses include making tiny parts for watches. At the same time, large panels with a certain surface finish may cover the entire building.

Some industries where stainless steel is widely used:

Food and Catering

chemical

Medical device manufacturing

Architecture and Construction

household appliances

Offshore and shipbuilding

Car manufacturer

Energy and Industry

Types of stainless steel

Stainless steel is available in a variety of grades and finishes, depending on the environment the metal is expected to withstand. Based on their microstructure, they can be divided into four major categories.

Austenitic stainless steel

Austenitic stainless steel has austenite as its main microstructure. Austenite is a solid solution of iron and carbon that forms above a critical temperature of 723°C. This stainless steel series displays high toughness and impressive high temperature resistance.

70% of all stainless steel is austenitic. It contains at least 16% chromium and 6% nickel.

Austenite stabilizers are elements added to promote the formation of austenite microstructure. This stainless steel grade is a non-magnetic metal and cannot be hardened by heat treatment. Corrosion resistance can be modified according to the use environment.

ferritic stainless steel

Ferritic steels usually contain only chromium as an alloying element. Chromium content ranges from 10.5 to 18%. They have average corrosion resistance and poor manufacturing characteristics. Heat treatment methods also do not help harden the metal.

They generally have better engineering capabilities than austenitic steels. Unlike austenitic stainless steels, they are magnetic. They also have good resistance to stress corrosion, which reduces wear on corrosive materials.

Duplex stainless steel

Duplex stainless steel is a mixture of austenitic and ferritic stainless steels. Therefore, it has the properties of its two components. It has high chromium and low nickel concentration. Duplex stainless steel has unique advantages due to its high tensile strength and good weldability.

It shows good resistance to stress corrosion, but not as well as ferritic grades. It is tougher than ferritic grades but weaker than austenitic grades.

martensitic stainless steel

This type of stainless steel is composed of high carbon and low chromium content. Like ferrite grades, it is magnetic. It does show poorer weldability compared to other grades, but it has higher hardenability and can be heat treated to improve performance.

Martensitic stainless steels have lower corrosion resistance than austenitic and ferritic stainless steels with the same chromium and alloy content.

precipitation hardened stainless steel

This subgroup provides a combination of austenitic and martensitic properties. Hardening is achieved by adding one or more elements such as aluminum, molybdenum, niobium, titanium and copper.

It is capable of producing high tensile strength through heat treatment. It contains chromium and nickel as alloying elements. These grades are used in high-speed applications such as turbine blades.