|

Property |

2205 |

UR52N+ |

|

Density (g.cm3) |

7.805 |

7.810 |

|

Modulus of Elasticity (GPa) |

200 |

205 |

|

Electrical Resistivity (Ω.m) |

0.85 x 10-6 |

0.85 x 10-6 |

|

Thermal Conductivity (W/m.K) |

19 at 100 °C |

17 at 100 °C |

|

Thermal Expansion (m/m.K) |

13.7 x 10-6 to 100 °C |

13.5 x 10-6 to 200 °C |

|

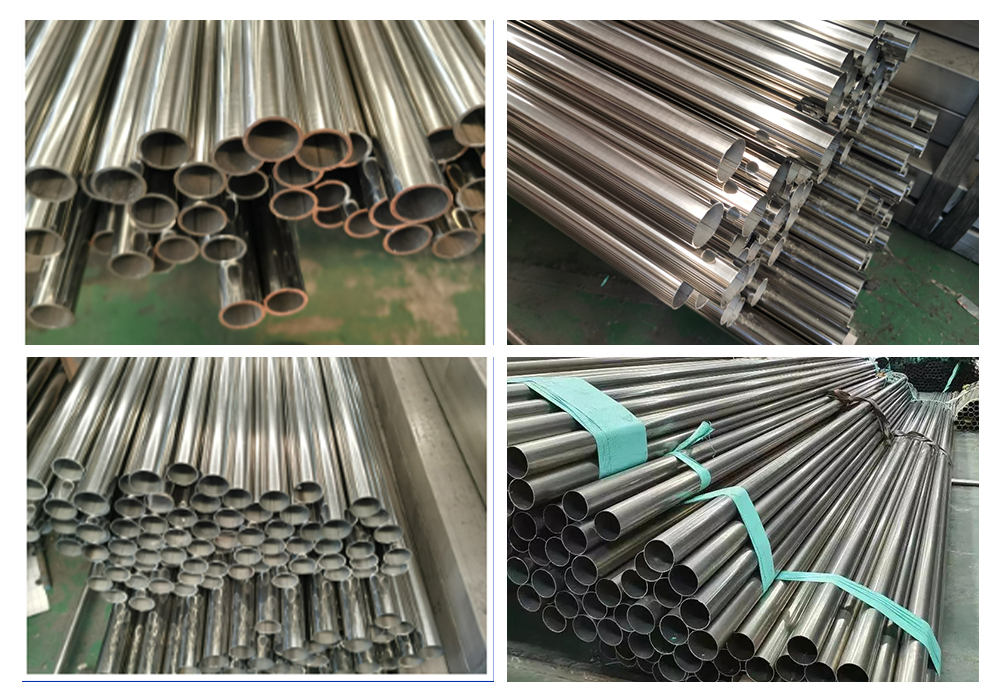

American Standard |

Austenitic Steel: TP304,TP304L,TP304H, TP304N, TP310S,TP316,TP316L,TP316Ti,TP316H, TP317,TP317L, TP321, TP321H,TP347, TP347H,904L… Duplex Steel : S32101,S32205,S31803,S32304,S32750, S32760 Others:TP405,TP409, TP410, TP430, TP439,... |

.jpg)