| ASTM B622 Hastelloy C22 Seamless Tubes Specification | ASTM B622 / ASME SB622 / UNS N010276 / UNS NO6022 |

| ASTM B622 Hastelloy C22 Seamless Tubes Grades | ASTELLOY C276 / HASTELLOY C22 / ALLOY C276 / ALLOY C22 |

| ASTM B622 Hastelloy C22 Seamless Tubes Type | ot Rolled / Cold Drawn / Welded / ERW |

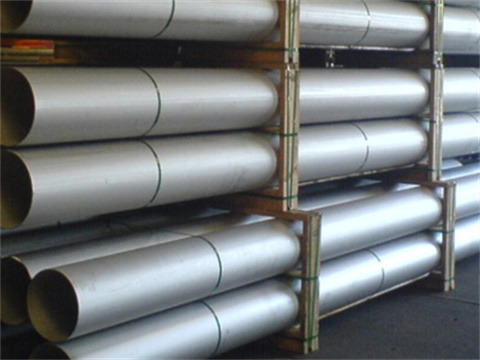

| ASTM B622 Hastelloy C22 Seamless Tubes Outer Diameter Size | Seamless - 1/4" NB to 6" NB (Nominal Bore Size) Welded / ERW- 1" NB to 16" NB (Nominal Bore Size) |

| ASTM B622 Hastelloy C22 Seamless Tubes Wall Thickness | Schedule 10 to Schedule 160 |

| ASTM B622 Hastelloy C22 Seamless Tubes Length | 5 to 7 Meters, 09 to 13 Meters, Single Random Length, Double Random Length And Customize Size. |

| ASTM B622 Hastelloy C22 Seamless Tubes Ends | Plain Ends / Beveled Ends |

| ASTM B622 Hastelloy C22 Seamless Tubes Delivery Conditions | As Rolled, Cold Drawn, Hot Finish, Stress Relieved, Annealed, Hardened, Tempered |

| ASTM B622 Hastelloy C22 Seamless Tubes Coating | Electropolish, Mechanical Polish, Satin Finish, Passivated |

| ASTM B622 Hastelloy C22 Seamless Tubes Other Testing | NACE MRO175, Hardness Test, Flare, Hydrostatic Test, Eddy Current test, Grain Size Test, Eddy Current, Annealed, Tempered, Stress Relieved etc. |

| ASTM B622 Hastelloy C22 Seamless Tubes Dimension | All Pipes Is Manufactured and Inspected / Tested to the Relevant standards including ASTM And ASME |

| ASTM B622 Hastelloy C22 Seamless Tubes Value Added Services | Draw / Expansion / Machining / Sand Blasting / Shot Blasting / Heat Treatment |

| ASTM B622 Hastelloy C22 Seamless Tubes Packaging | Loose / Bundle / Wooden Pallet / Wooden box-a / Plastic Cloth Wraps / Plastic End Caps / Beveled Protector |

| ASTM B622 Hastelloy C22 Seamless Tubes Shipment & Transportation | By Road - Truck / Train, By Sea - Break-bulk Conventional Vessel / FCL (Full Container Load) / LCL (Less Container Load) / 20 Feet Container / 40 Feet Container / 45 Feet Container / High Cube Container / Open Top Container, By Air - Freighter Civil Passenger and Cargo Planes |

| ASTM B622 Hastelloy C22 Seamless Tubes Material Test Certificate | Manufacturer Test Certificate As Per EN10204 3.1, 3.2 / Laboratory Test Certificate From NABL Approved Lab. / Under Third Party Inspection Agency Like SGS, TUV, DNV, LLOYDS, ABS ETC |

The following table shows the chemical composition of Hastelloy(r) C22(r).

| Element | Content (%) |

| Chromium, Cr | 20-22.5 |

| Molybdenum, Mo | 12.5-14.5 |

| Tungsten, W | 2.5-3.5 |

| Cobalt, Co | 2.5 min |

| Iron, Fe | 2-6 |

| Manganese. Mn | 0.5 max |

| Vanadium, V | 0.35 min |

| Silicon, Si | 0.08 max |

| Phosphorus, P | 0.02 max |

| Sulfur, S | 0.02 max |

| Carbon, C | 0.015 max |

| Nickel, Ni | Remainder |

The physical properties of Hastelloy(r) C22(r) are outlined in the following table.

| Properties | Metric | Imperial |

| Density | 8.69 g/cm³ | 0.314 lb/in³ |

| Melting point | 1399°C | 2550°F |

The Mechanical Properties of Hastelloy(r) C22(r) are displayed in the following table.

| Properties | Metric | Imperial |

| Elastic modulus | 206 MPa | 29878 psi |

The thermal properties of Hastelloy(r)C22(r) are given in the following table.

| Properties | Metric | Imperial |

| Thermal conductivity (at 100°C/212°F) | 11.1 W/mK | 6.4 BTU in/hr.ft².°F |