| Grades | Stainless Steel J1, J2, J4, 201, 202, 301, 304, 304H, 304L, 309, 309S, 310, 310S, 316, 316L, 316Ti, 321, 321H, 347, 409, 410, 410S, 420, 430, 441, 904L |

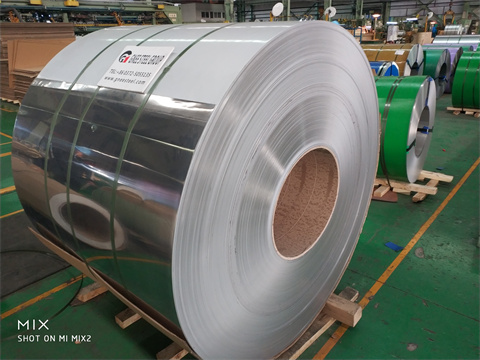

| Thickness | 0.02mm – 5.0mm |

| Width | 3.2mm – 1500mm |

| Length | 2000mm, 2440mm, 3000mm, 5800mm, 6000mm, AS PER CUSTOMER’S REQUIREMENT |

| Type of Material | STAINLESS STEEL SOFT, DEEP DRAW, EXTRA DEEP DRAW, QUARTER HARD, HALF HARD, FULL HARD. |

| Form | Coil / Strip |

| Test Certificate | Yes. |

| Finish | NO.1, 2B, 2D, 2H, 2R, No.4, HAIRLINE, SCOTCH BRITE, SATIN FINISH, NO.8, BA. |

| Make | JINDAL, BAHRU, POSCO KOREA, POSCO THAINOX, COLUMBUS, ACERINOX, APERAM, TISCO, NISSHIN, NIPPON AND MANY MORE MILLS. |

| Grades | SS 430 |

| Tensile Strength (MPa) min | 450 |

| Yield Strength 0.2% Proof (MPa) min | 205 |

| Elongation (% in 50mm) min | 22 |

| Hardness Rockwell B (HR B) max | 89 |

| Hardness Brinell (HB) max | 183 |

| Grade | C | Mn | Si | P | S | Cr | Ni | Mo | |

| 430 | Min | – | – | – | – | – | 16.0 | – | – |

| max | 0.12 | 1.00 | 1.00 | 0.040 | 0.030 | 18.0 | 0.75 | – |

| STANDARD | UNS | JIS | WERKSTOFF NR. | AFNOR | BS | GOST | EN |

| SS 430 | S43000 | SUS 430 | 1.4016 | – | – | – | – |

|

Density (lb./ in^2) @ RT |

0.278 |

|

|

Modulus of Elasticity in Tension (psi x 10^6) |

29.0 |

|

|

Specific Heat (BTU/°F/lb.) |

32 to 212 °F |

0.11 |

|

Thermal Conductivity (BTU/hr/ft^2/ft) |

212°F |

13.8 |

|

932°F |

15.0 |

|

|

Mean Coefficient of Thermal Expansion (in. x 10^-6 per °F) |

32 to 212°F |

5.7 |

|

32 to 932°F |

6.2 |

|

|

Electrical Resistivity (micro ohms - cm) |

at 70°F |

60.0 |

|

Melting Point Range (°F) |

2600 - 2750 |

|

|

Oxidation Resistance - Continuous Service(°F) |

1500 |