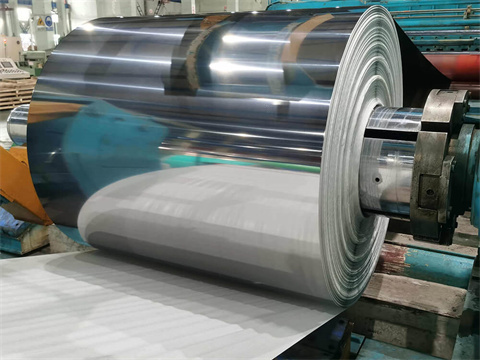

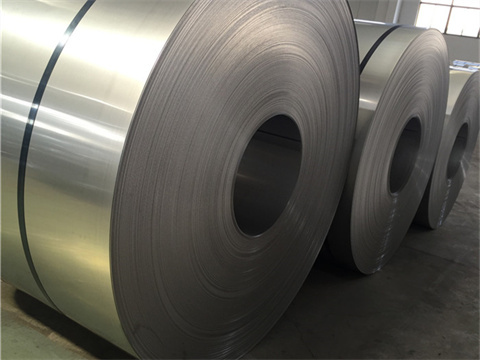

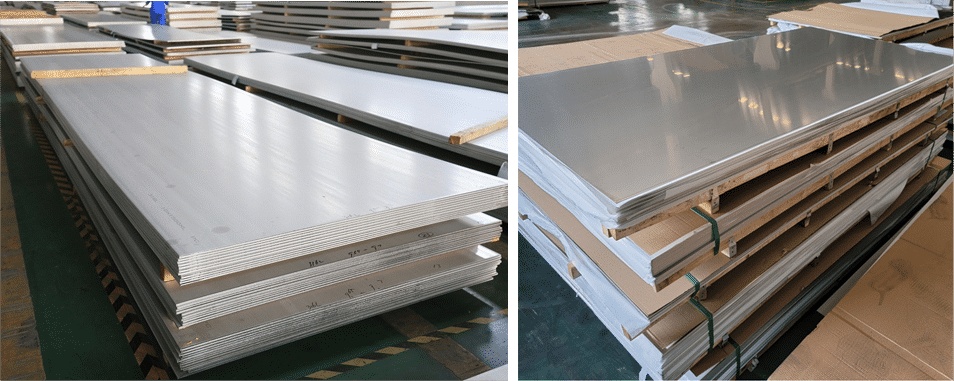

GNEE Steel is the foremost and leading supplier, exporter and manufacturer of high-quality 904L Stainless Steel Coils in China. These SS Coils are available in different dimensions, specifications, forms, and types. Using high-quality materials and modern machinery, we manufacture these SS 904L Coils and supplied them all over the world.

Grade 904L Stainless Steel Coils are made up of non-stabilized austenitic stainless contains 25% chromium and 4.5% nickel with low carbon content. This alloy stainless steel coil has an addition of copper to improve resistance to strong reducing acids like sulphuric acids. Moreover, these Stainless Steel 904L Coils are also resistant to stress corrosion cracking and crevice corrosion.

Non-magnetic UNS N08904 Stainless Steel Coils possess excellent toughness, formability, and weldability due to low carbon content. We offered these type 904L SS Coils in several industries such as oil & gas refineries, marine appliances, paper & pulp processing, food processing, heat exchangers, boiler industries and many more. Our manufacturing unit manufactured these coils in Indian as well as International Standards including ASME, ASTM, ANSI, AISI, BS, IS, DIN, JIS & more.

We are expertized in producing and delivering customized dimensions products at the most attractive price range. If you are looking to buy these ASTM B625 Stainless Steel 904L Coils then Contact Us Now and get Free estimation from us in minutes.

| Grades | Stainless Steel J1, J2, J4, 201, 202, 301, 304, 304H, 304L, 309, 309S, 310, 310S, 316, 316L, 316Ti, 321, 321H, 347, 409, 410, 410S, 420, 430, 441, 904L |

| Thickness | 0.02mm – 5.0mm |

| Width | 3.2mm – 1500mm |

| Length | 2000mm, 2440mm, 3000mm, 5800mm, 6000mm, AS PER CUSTOMER’S REQUIREMENT |

| Type of Material | STAINLESS STEEL SOFT, DEEP DRAW, EXTRA DEEP DRAW, QUARTER HARD, HALF HARD, FULL HARD. |

| Form | Coil / Strip |

| Test Certificate | Yes. |

| Finish | NO.1, 2B, 2D, 2H, 2R, No.4, HAIRLINE, SCOTCH BRITE, SATIN FINISH, NO.8, BA. |

| Make | JINDAL, BAHRU, POSCO KOREA, POSCO THAINOX, COLUMBUS, ACERINOX, APERAM, TISCO, NISSHIN, NIPPON AND MANY MORE MILLS. |

| Grades | SS 904L |

| Density | 8 |

| Melting Point | 1300 – 1390 ℃ |

| Tensile Strength | 490 |

| Yield Strength (0.2%Offset) | 220 |

| Elongation | 35% min |

| Hardness (Brinell) | – |

| Grade | C | Mn | Si | P | S | Cr | Ni | Mo | N | Cu | |

| 904L | Min | – | – | – | – | – | 19.0 | 23.00 | 4.00 | 0.10 | 1.00 |

| max | 0.20 | 2.00 | 1.00 | 0.045 | 0.035 | 23.0 | 28.00 | 5.00 | 0.25 | 2.00 |

| STANDARD | UNS | JIS | WERKSTOFF NR. | AFNOR | BS | GOST | EN |

| SS 904L | N08904 | SUS 904L | 1.4539 | Z2 NCDU 25-20 | 904S13 | – | X1NiCrMoCu25-20-5 |

| EN-standard Steel no. k.h.s DIN |

EN-standard Steel name |

SAE grade | UNS |

| 1.4109 | X65CrMo14 | 440A | S44002 |

| 1.4112 | X90CrMoV18 | 440B | S44003 |

| 1.4125 | X105CrMo17 | 440C | S44004 |

| 440F | S44020 | ||

| 1.4016 | X6Cr17 | 430 | S43000 |

| 1.4408 | G-X 6 CrNiMo 18-10 | 316 | S31600 |

| 1.4512 | X6CrTi12 | 409 | S40900 |

| 410 | S41000 | ||

| 1.4310 | X10CrNi18-8 | 301 | S30100 |

| 1.4318 | X2CrNiN18-7 | 301LN | |

| 1.4307 | X2CrNi18-9 | 304L | S3043 |

| 1.4306 | X2CrNi19-11 | 304L | S30403 |

| 1.4311 | X2CrNiN18-10 | 304LN | S30453 |

| 1.4301 | X5CrNi18-10 | 304 | S30400 |

| 1.4948 | X6CrNi18-11 | 304H | S30409 |

| 1.4303 | X5CrNi18-12 | 305 | S30500 |

| X5CrNi30-9 | 312 | ||

| 1.4841 | X22CrNi2520 | 310 | S31000 |

| 1.4845 | X 5 CrNi 2520 | 310S | S31008 |

| 1.4541 | X6CrNiTi18-10 | 321 | S32100 |

| 1.4878 | X12CrNiTi18-9 | 321H | S32109 |

| 1.4404 | X2CrNiMo17-12-2 | 316L | S31603 |

| 1.4401 | X5CrNiMo17-12-2 | 316 | S31600 |

| 1.4406 | X2CrNiMoN17-12-2 | 316LN | S31653 |

| 1.4432 | X2CrNiMo17-12-3 | 316L | S31603 |

| 1.4435 | X2CrNiMo18-14-3 | 316L | S31603 |

| 1.4436 | X3CrNiMo17-13-3 | 316 | S31600 |

| 1.4571 | X6CrNiMoTi17-12-2 | 316Ti | S31635 |

| 1.4429 | X2CrNiMoN17-13-3 | 316LN | S31653 |

| 1.4438 | X2CrNiMo18-15-4 | 317L | S31703 |

| 1.4362 | X2CrNi23-4 | 2304 | S32304 |

| 1.4462 | X2CrNiMoN22-5-3 | 2205 | S31803/S32205 |

| 1.4501 | X2CrNiMoCuWN25-7-4 | J405 | S32760 |

| 1.4539 | X1NiCrMoCu25-20-5 | 904L | N08904 |

| 1.4529 | X1NiCrMoCuN25-20-7 | N08926 | |

| 1.4547 | X1CrNiMoCuN20-18-7 | 254SMO | S31254 |

| Surface Finish | Definition | Application |

| 2B | Finished by heat treatment , picking or equipvalent cold rolling , followed by skin pass to obtain adequate luster surface. | With bright and smooth surface ,easy for further grinding to obtain brighter surface ,suitable for medical instruments ,milk containers ,tableware and so on. |

| BA | Bright heat treatment after cold rolling. | Structual members .etc.kitchen utensil ,cutlery ,eleltric applicances ,medical instruments ,building decorations ,etc. |

| NO.3/NO.4 | Polished with No.150-240 abrasives. | Milky food processing equipment , medicalinstruments ,building decorations. |

| HL | Finshed by polishing with abrasives of suitable grain size to obtain continuous streaks. | Building decorations ,such as elevators ,escalators ,door etc. |

| 6K/8K | A mirror-like reflective surface ,which is obtained by polishing with successively finer abrasives and buffing extensively with all gritlines are removed. | Buliding entrances,bulkding column casting ,elevator's wall doors ,counters,sculptur |