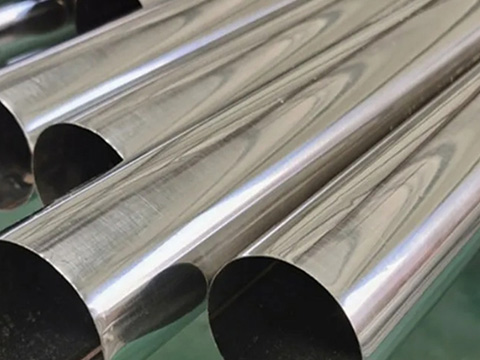

EN 1.4301 Stainless Steel Tube (X5CrNi18-10) is a conventional austenitic stainless steel with good resistance to atmospheric, organic and inorganic chemicals. This material is widely used due to its excellent resistance to intergranular corrosion, good cold deformability, good deep drawability and weldability.

EN X5CrNi18-10 Stainless Steel Round Tube is non-magnetic in the annealed condition, but may become slightly magnetic due to the addition of martensite or ferrite during cold working or welding.

What are the differences between AISI 304 (1.4301) and 316 (1.4401) stainless steel pipes?

AISI 304 and 316 have similar values for hardness (Brinell hardness), elastic modulus and tensile strength. AISI 316 has a higher yield strength at 200 MPa (190 MPa for 304) and AISI 304 has a higher melting point (1450°C for 316 vs. 1400°C). Due to AISI 316, it generally has better corrosion resistance than 304.

Implementation standards

European standards: EN 10216-5 (seamless steel pipe), EN 10305-1 (welded steel pipe).

Equivalent grades: USA: ASTM A269/A312 (304), UNS S30400

China: GB/T 14976 (06Cr19Ni10)

Japan: JIS G3459 (SUS304)

DIN 1.4301 Pipes Seamless Pipes Equivalent Grades

| Grade | 304 | |

| UNS No | S30400 | |

| Old British | BS | 304S31 |

| En | 58E | |

| Euronorm | No | 1.4301 |

| Name | X5CrNi18-10 | |

| Swedish SS | 2332 | |

| Japanese JIS | SUS 304 | |

| Element | Content Range | Function |

|---|---|---|

| Chromium (Cr) | 17.5–19.5% | Forms a passive film to enhance corrosion and oxidation resistance |

| Nickel (Ni) | 8.0–10.5% | Stabilizes the austenitic structure, improving toughness and low-temperature performance |

| Carbon (C) | ≤0.07% | Low-carbon design reduces intergranular corrosion risk and ensures weldability |

| Silicon (Si) | ≤1.0% | Improves machinability and controls oxide film formation |

| Manganese (Mn) | ≤2.0% | Adjusts strength and balances alloy cost |

| Grade | DIN 1.4301 | |

|---|---|---|

| Tensile Strength (MPa) min | 515 | |

| Yield Strength 0.2% Proof (MPa) min | 205 | |

| Elongation (% in 50mm) min | 40 | |

| Hardness | Rockwell B (HR B) max | 92 |

| Rockwell B (HR B) max | 201 | |