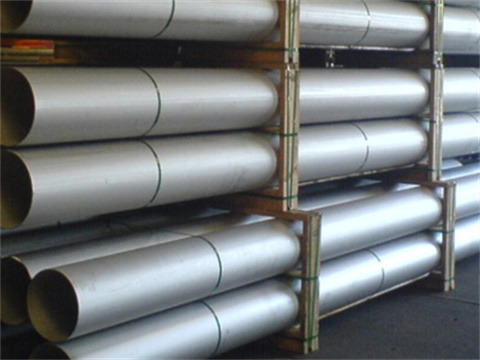

Duplex stainless steel is a chemical composition which is a mixture of approximately equal parts of ferrite and austenite. The mixture of these components makes the duplex stainless steel pipes twice as strong as regular austenitic or ferritic stainless steel pipes. Duplex stainless steel pipes show excellent stress corrosion cracking resistance (SCC). Duplex stainless steel pipes are resolute and tough and can manage temperatures up to minus 80 degrees C. The strength of the duplex stainless steel pipes makes it possible to weld on the thicker sections of the pipe. However, this should be done with uttermost care. These pipes offer high strength which in turn leads to weight saving. Compared to most pipes in the industry, duplex stainless steel pipes have one of the best price stability. Due to its low cost and weight saving, in the recent years, duplex stainless steel pipes have been growing in popularity as an alternative to nickel alloy based pipes.

There are also two types of duplex stainless steel pipes that are manufactured they are :

Seamless duplex stainless steel pipes :A seamless duplex stainless steel pipe is manufactured from solid round billets, thus there are no welding or joints.

Welded duplex stainless steel pipes :welded duplex stainless steel pipes are pipes that are brought to a union by applying high levels of heat or by applying accelerated pressure.

Duplex Stainless Steel pipes serve many different applications in these industries :

Chemical Process

Petrochemical

Oil & Gas

Pharmaceutical

Geothermal

Sea Water

Water Desalination

LNG (Liquefied Natural Gas)

Biomass

Mining

Utilities

Nuclear Power

Solar Power