17-4PH stainless steel plate heat treatment

Solution treatment: heating at 1020~1060℃, followed by rapid cooling. The structure after solution treatment is mainly quenched martensite + residual austenite + a small amount of ferrite. After aging treatment, fine and dispersed strengthening phases are precipitated in the alloy, effectively improving the strength and hardness of the alloy.

630 stainless steel plate application areas

Aerospace: used to manufacture aircraft structural parts and engine parts.

Petrochemical: used to manufacture pipelines, valves and reactors under high temperature and high pressure.

Marine engineering: used to manufacture offshore platforms, ships and diving equipment, etc.

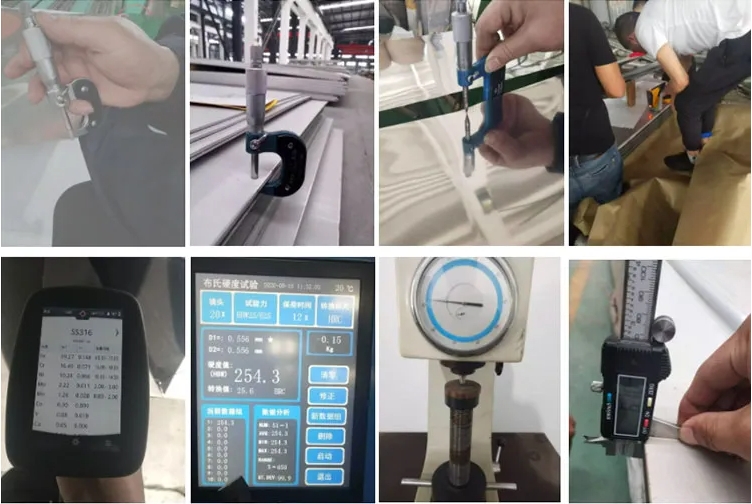

630 stainless steel mechanical properties:

Density: Approximately 7.75 g/cm3

Specific heat: 0.11 BTU/lb-°F @ 70°F (460 J/kg-°C @ 20°C)

Modulus of elasticity: 28.5 x 10^6 psi (196 GPa)

Thermal conductivity: 10.6 BTU-in/ft² - hr-°F (18.3 W/m-°C) at 212°F (100°C)

.jpg)

(3).jpg)

Q: Can we visit your factory?

A: Warmly welcome. Once we have your schedule, we will arrange the professional sales team to follow up your case.

Q: Can you provide OEM/ODM service?

A: Yes. Please feel free to contact us for more detail discussion.

Q.What is 1.4542 stainless steel equivalent to?

A.630 stainless steel is one of the newest stainless steel grades discovered in the 1960s. According to the EN standard, this grade is written as 1.4542 or X5CrNiCuNb16-4 or 17-4 PH.